Brief introduction and practical application of PP plastic particles

Release time:

2021-05-11

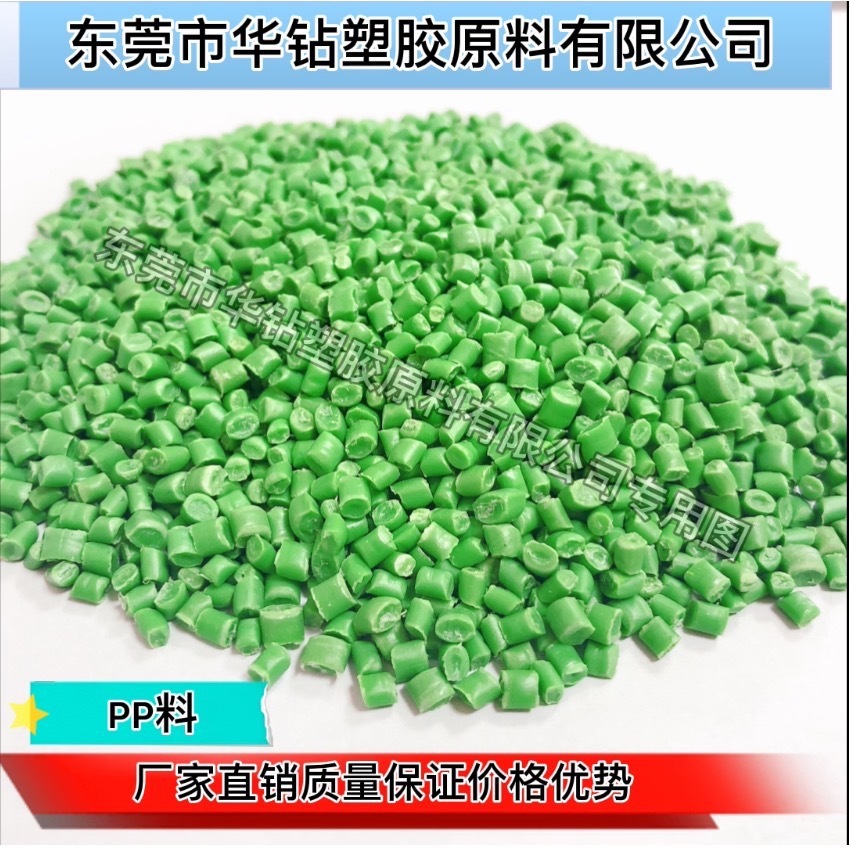

Pp plastic particles is a non-toxic and tasteless Milky White crystalline polymer with high crystallinity and regular structure, so it has excellent mechanical properties, and its yield strength, tensile strength, compression strength, hardness and elasticity are higher than HDPE. Its melting point is 164~170, and the product can be sterilized at a temperature above 100 degrees. Polypropylene has good chemical stability, can be eroded by concentrated nitric acid, and is relatively stable to other chemical reagents. Processing methods: injection molding, extrusion, hollow and rotational molding.

pp plastic particles is a non-toxic and tasteless Milky White crystalline polymer with high crystallinity and regular structure, so it has excellent mechanical properties, and its yield strength, tensile strength, compression strength, hardness and elasticity are higher than HDPE. Its melting point is 164~170, and the product can be sterilized at a temperature above 100 degrees. Polypropylene has good chemical stability, can be eroded by concentrated nitric acid, and is relatively stable to other chemical reagents. Processing methods: injection molding, extrusion, hollow and rotational molding.

PP plastic particles is one of the four general plastic materials, with excellent comprehensive performance, excellent chemical stability, excellent molding performance and relatively low price. But it also has the disadvantages of low strength, coefficient, low hardness, poor low temperature impact strength, large molding shrinkage and easy aging. Therefore, it must be modified so that it can be adapted to the needs of the product.

PP plastic particles are new product materials combined with cutting-edge technology, and all industries need the penetration of PP particles. The material is refined by high temperature effect by science and technology. It has the properties of high temperature resistance, not afraid of corrosion, heat preservation and moisture-proof, and has been applied to life. Due to the high melting point of the particles, a variety of processes are required in the processing process. It is not easy to dissolve even at a high temperature of 1,000 degrees Celsius, has stable chemical properties, and does not undergo chemical reactions at room temperature, so the processed products have high durability and will not rot. The quality of the plastic produced is also very good, avoiding white pollution and contributing to environmental protection.

PP plastic particles do not contain toxins, do no harm to the human body, can form a shape, relieve the gravity exerted by the outside world, and the small fluid resistance can ensure the horsepower of the system operation, and greatly improve the operating state of the product. The quality of this particle is very light, only the 1/7 of metal steel, and the adhesion degree ensures the adhesion of the product. This material has strong strength and good toughness. It is a material required for processing important industrial products. This kind of particle contains rich thermoplastic advanced molecular materials. The strict organizational structure can ensure the quality of products when processing industrial products. Can be used in any complex environment. Because the anti-acid and anti-alkali properties are very superior, can be dissolved organically at a certain temperature, greatly ensuring the stability of the chemical properties of things, even if used for a long time will not appear the phenomenon of deterioration.

Related News

Follow Us

Dongguan huazuan plastic material Co., Ltd.

Add.: No. 78, Qiaoli Beimen Industrial Zone, changping town, Dongguan City

Tel: +86-0769 82020719

Sales one: Mr. Chen +86-13802397965

Sales 2: Miss Xia +86-13922971175

Sales 3: Miss Feng +86-13922918732

Fax: +86-769 82308699

Email: lindaxia@cnhzsj.com

Copyright©2023 Dongguan huazuan plastic material Co., Ltd. All Rights Reserved

绿美佳塑胶

Online Message