Dive into the World of Black High Gloss PP: Properties and Applications

Release time:

2024-10-22

Dive into the World of Black High Gloss PP: Properties and Applications 1. Introduction to Black High Gloss Polypropylene (PP) Black High Gloss Polypropylene (PP) is an innovative thermoplastic polymer that has gained significant attention in the manufacturing and design industries. Known for its sleek appearance and impressive physical properties, this material offers a unique blend of aesthetic

Dive into the World of Black High Gloss PP: Properties and Applications

1. Introduction to Black High Gloss Polypropylene (PP)

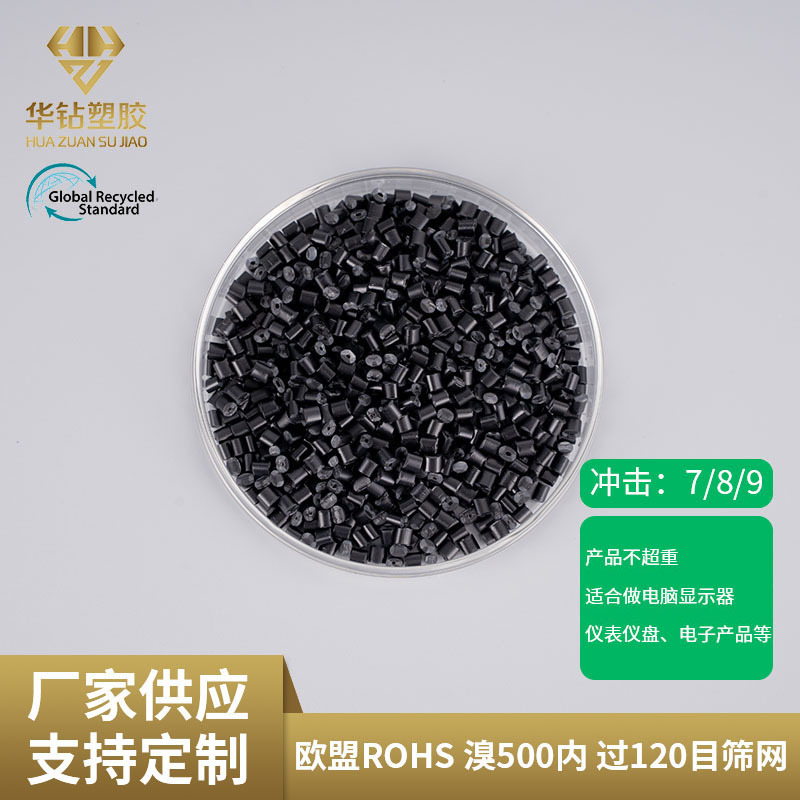

Black High Gloss Polypropylene (PP) is an innovative thermoplastic polymer that has gained significant attention in the manufacturing and design industries. Known for its sleek appearance and impressive physical properties, this material offers a unique blend of aesthetic appeal and practical functionality. We will delve into the characteristics, benefits, and diverse applications of Black High Gloss PP, illustrating why it is a preferred choice for manufacturers and designers alike.

2. Understanding Polypropylene: The Basics

2.1 What is Polypropylene?

Polypropylene is a versatile thermoplastic polymer that is widely used in various applications. Derived from the polymerization of propylene monomers, it is known for its chemical resistance, lightweight nature, and flexibility. Polypropylene can be produced in various forms, including homopolymers, copolymers, and block copolymers, each with unique properties tailored to specific uses.

2.2 The Characteristics of High Gloss Finish

The high gloss finish of Black High Gloss PP not only enhances its visual appeal but also provides several functional benefits. This finish reflects light effectively, giving products an elegant and modern look. High gloss surfaces are also easier to clean and maintain, making them ideal for a variety of applications from consumer goods to industrial components.

3. Properties of Black High Gloss PP

3.1 Physical Properties

Black High Gloss PP boasts several advantageous physical properties, including:

- **Durability**: It has excellent resistance to impact and stress, making it suitable for demanding environments.

- **Chemical Resistance**: This material withstands exposure to a wide range of chemicals, ensuring longevity and reliability.

- **Thermal Stability**: Black High Gloss PP maintains its integrity across a broad temperature range, making it ideal for both hot and cold applications.

3.2 Aesthetic Qualities

The aesthetic properties of Black High Gloss PP are equally impressive:

- **High Gloss Finish**: This feature provides a luxurious look, making it perfect for consumer products that require a premium feel.

- **Color Consistency**: The deep black color of the high gloss finish remains uniform, enhancing product presentation.

- **Light Reflection**: The glossy surface reflects light beautifully, adding visual interest and depth to product designs.

4. Applications of Black High Gloss PP

Black High Gloss PP is used across various industries due to its exceptional properties. Here are some of the primary applications:

4.1 In the Automotive Industry

In the automotive sector, Black High Gloss PP is used for interior and exterior components. Its lightweight nature contributes to fuel efficiency, while its high gloss finish enhances the vehicle's aesthetics. Components such as dashboards, trims, and exterior panels benefit from the material's durability and resistance to weathering.

4.2 Consumer Goods and Electronics

Black High Gloss PP is increasingly popular in consumer goods, especially in electronics. From smartphone cases to kitchen appliances, the high gloss finish adds a touch of sophistication. Additionally, the material's durability helps protect against everyday wear and tear, ensuring products remain looking new longer.

4.3 Packaging Solutions

In packaging, Black High Gloss PP is favored for its ability to create visually appealing containers. It is commonly used in premium product packaging, including cosmetics and high-end consumer goods. The material's resistance to moisture and chemicals ensures that the products inside remain secure and intact.

4.4 Home and Interior Design

Interior designers utilize Black High Gloss PP to create striking furniture, fixtures, and decor items. Its reflective surface can enhance the perceived space in a room, making it a popular choice for modern design aesthetics. Additionally, its ease of maintenance makes it suitable for high-traffic areas.

5. Advantages of Using Black High Gloss PP

The benefits of choosing Black High Gloss PP extend beyond its aesthetic appeal. Key advantages include:

5.1 Cost-Effectiveness

Black High Gloss PP offers an affordable solution for manufacturers seeking high-quality materials. Its durability reduces the need for frequent replacements, contributing to lower long-term costs.

5.2 Environmental Considerations

As sustainability becomes increasingly important, Black High Gloss PP stands out due to its recyclability. Manufacturers can create environmentally-friendly products without compromising on performance or aesthetics.

5.3 Customization Potential

The versatility of Black High Gloss PP allows for extensive customization options. It can be molded into various shapes and sizes, enabling manufacturers to design products that meet specific market demands.

6. Processing Techniques for Black High Gloss PP

6.1 Injection Molding

Injection molding is one of the most common methods for processing Black High Gloss PP. This technique allows for precise control over the shape and finish of the final product, ensuring consistency and quality in mass production.

6.2 Extrusion

Extrusion is another popular technique used to create sheets, films, and other profiles from Black High Gloss PP. This method is particularly useful for producing long continuous products, such as panels and packaging materials.

6.3 Thermoforming

Thermoforming involves heating a sheet of Black High Gloss PP and forming it into a desired shape using molds. This technique is beneficial for creating complex shapes and is widely used in packaging and consumer product design.

7. Best Practices for Working with Black High Gloss PP

To maximize the benefits of Black High Gloss PP, it is essential to follow best practices during both the manufacturing and end-use stages.

7.1 Proper Storage

Store Black High Gloss PP in a cool, dry place to prevent degradation. Protect it from direct sunlight to maintain its color and finish.

7.2 Cleaning and Maintenance

Regular cleaning with mild detergents is recommended to retain the material's glossy appearance. Avoid abrasive cleaners that could scratch the surface.

7.3 Quality Control

Implement stringent quality control measures throughout the production process to ensure that the final products meet the desired specifications and standards.

8. Future Trends in Black High Gloss PP Applications

As technology and consumer preferences evolve, the applications of Black High Gloss PP are expected to expand. Trends to watch include:

8.1 Increased Use in Sustainable Design

With growing demand for eco-friendly products, manufacturers are likely to explore sustainable alternatives to traditional materials, positioning Black High Gloss PP as a viable option due to its recyclability.

8.2 Advancements in Manufacturing Technology

Innovation in manufacturing technologies may lead to improved processing techniques for Black High Gloss PP, enhancing its properties and broadening its applications.

8.3 Customization and Personalization Trends

As consumers increasingly seek personalized products, the customization potential of Black High Gloss PP will likely drive its use in bespoke designs across various industries.

9. Frequently Asked Questions (FAQs)

9.1 What are the primary benefits of using Black High Gloss PP?

Black High Gloss PP offers durability, chemical resistance, lightweight properties, and an attractive aesthetic, making it an ideal choice across many applications.

9.2 How can Black High Gloss PP be processed?

Black High Gloss PP can be processed through various methods, including injection molding, extrusion, and thermoforming.

9.3 Is Black High Gloss PP environmentally friendly?

Yes, Black High Gloss PP is recyclable and can be used to create eco-friendly products without sacrificing performance.

9.4 What industries benefit the most from Black High Gloss PP?

Industries including automotive, consumer goods, packaging, and interior design significantly benefit from the properties and applications of Black High Gloss PP.

9.5 How should I clean and maintain products made from Black High Gloss PP?

To maintain its appearance, clean products with mild detergents and avoid abrasive materials that could scratch the surface.

10. Conclusion

In conclusion, Black High Gloss Polypropylene is an exceptional material that combines aesthetic appeal with practical functionality. Its diverse properties and applications make it a valuable resource across various industries. As manufacturers continue to innovate and adapt to changing consumer preferences, the potential for Black High Gloss PP will only grow. Whether in automotive design, consumer electronics, packaging, or interior decor, this versatile material is poised to leave a lasting impact on the market.

Related News

Follow Us

Dongguan huazuan plastic material Co., Ltd.

Add.: No. 78, Qiaoli Beimen Industrial Zone, changping town, Dongguan City

Tel: +86-0769 82020719

Sales one: Mr. Chen +86-13802397965

Sales 2: Miss Xia +86-13922971175

Sales 3: Miss Feng +86-13922918732

Fax: +86-769 82308699

Email: lindaxia@cnhzsj.com

Copyright©2023 Dongguan huazuan plastic material Co., Ltd. All Rights Reserved

绿美佳塑胶

Online Message