LDPE polyethylene blown film

Release time:

2024-10-17

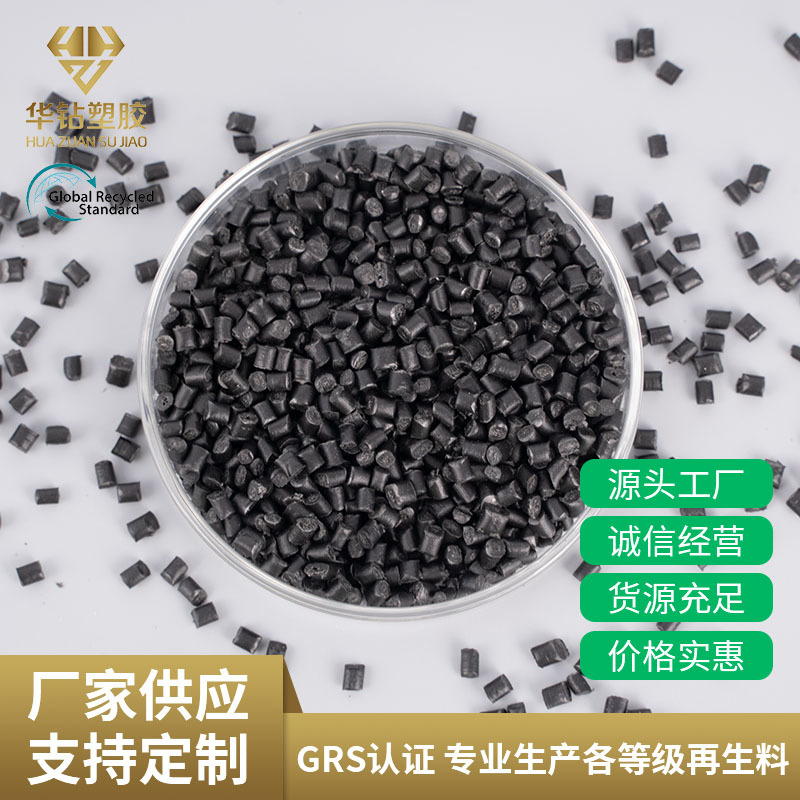

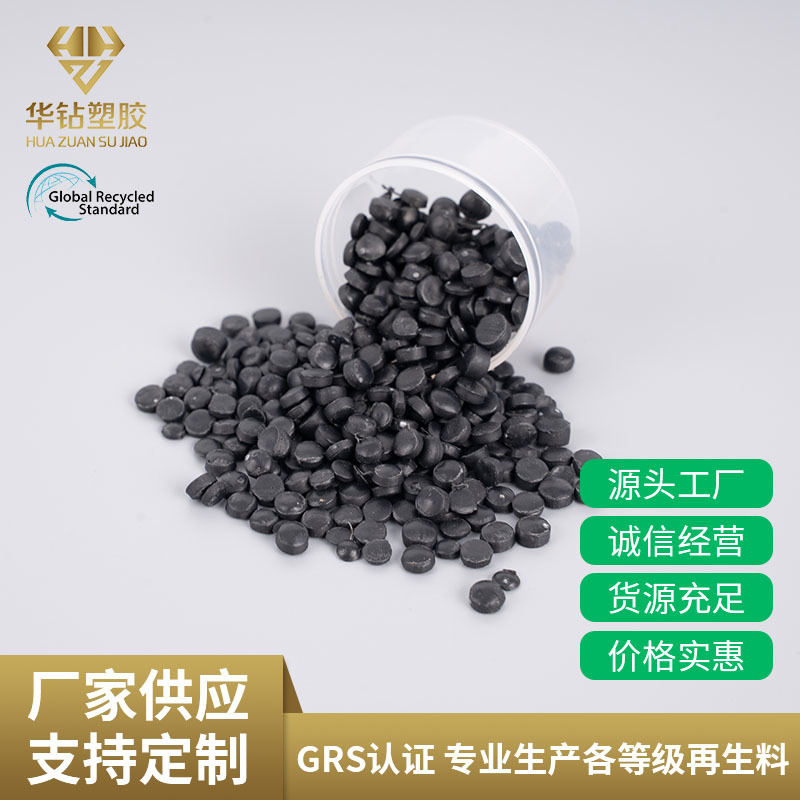

LDPE (Low-Density Polyethylene) polyethylene blown film is a versatile and widely used plastic material known for its excellent flexibility, toughness, and lightweight properties. This type of film is produced through a process called blowing, where heated LDPE granules are extruded through a circular die to form a tube, which is then inflated and cooled to create a thin film.

LDPE (Low-Density Polyethylene) polyethylene blown film is a versatile and widely used plastic material known for its excellent flexibility, toughness, and lightweight properties. This type of film is produced through a process called blowing, where heated LDPE granules are extruded through a circular die to form a tube, which is then inflated and cooled to create a thin film.

One significant advantage of LDPE blown film is its exceptional strength-to-weight ratio, making it ideal for packaging applications requiring durability and resistance to tears and punctures. The film's flexibility allows for easy handling and use in automatic packaging machines, while its moisture-proof barrier properties help protect packaged goods from environmental factors.

The manufacturing process of LDPE blown film involves several stages: resin selection, compounding, extrusion, cooling, collapsing, slitting, and winding. The choice of resin affects the film's final properties, such as thickness, clarity, and gloss. Additives may also be incorporated during the compounding stage to enhance specific characteristics like UV resistance or anti-blocking agents to prevent layers from sticking together.

Extrusion is the key step where the molten LDPE is formed into a thin tube. As the tube exits the die, it is inflated by air to stretch the polymer chains in all directions, creating a biaxially oriented structure that improves mechanical performance. The inflated bubble is then cooled down by air rings or water baths to solidify the film.

Once cooled, the film is collapsed and flattened before being slit into rolls of desired widths. These rolls can vary in thickness depending on their intended application, ranging from less than one micrometer for snack food packaging to several tens of micrometers for heavy-duty industrial uses.

In terms of applications, LDPE blown film is ubiquitous in everyday life. It is commonly found in grocery bags, trash bags, frozen food packaging, stretch film, and agricultural mulch films. Its biocompatibility also makes it suitable for use in medical and hygiene products such as surgical gloves and hospital gowns. Additionally, due to its recyclability, efforts are being made to increase the recycling rates of LDPE films to reduce environmental impact.

Overall, LDPE polyethylene blown film stands out for its combination of low cost, ease of processing, and adaptability to various end-use requirements, ensuring its continued popularity in the global marketplace.

Previous Page

Next Page

Related News

Follow Us

Dongguan huazuan plastic material Co., Ltd.

Add.: No. 78, Qiaoli Beimen Industrial Zone, changping town, Dongguan City

Tel: +86-0769 82020719

Sales one: Mr. Chen +86-13802397965

Sales 2: Miss Xia +86-13922971175

Sales 3: Miss Feng +86-13922918732

Fax: +86-769 82308699

Email: lindaxia@cnhzsj.com

Copyright©2023 Dongguan huazuan plastic material Co., Ltd. All Rights Reserved