What is PP recycled material like? How to shape? Do you know anything about it

Release time:

2023-01-03

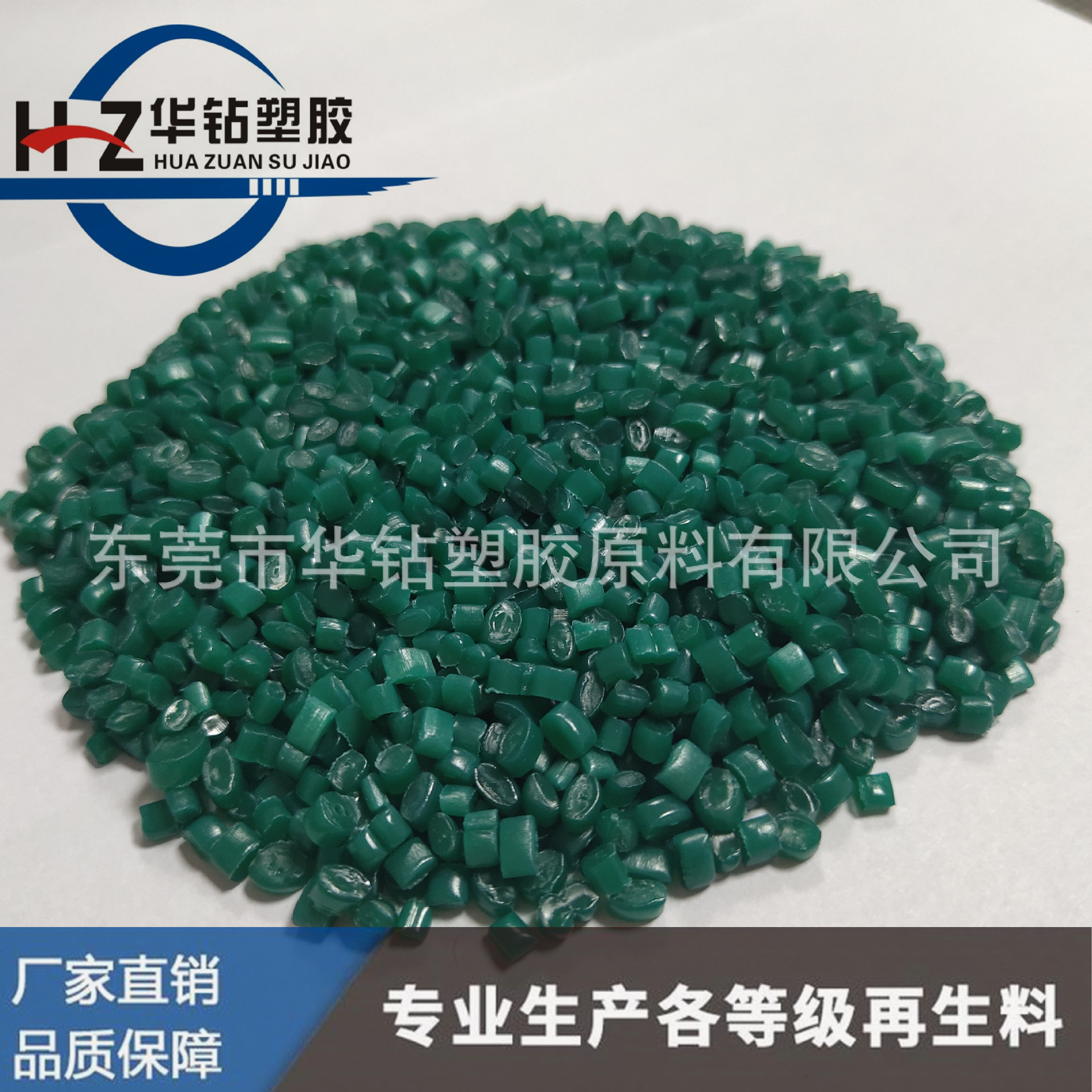

What is PP recycled material? How to carry out molding? Do you know anything about it? We can look at the following contents for relevant understanding. PP regenerants are crystalline polymers. Among the commonly used plastic particles, PP recycled materials are lighter, with a density of only 0.91g/cm3, which is smaller than water.

PP recycled materialWhat is it like? How to shape? Do you know anything about it? Below you can look at the following content for relevant understanding.

PP regenerants are crystalline polymers. In the commonly used plastic particles, PP recycled material is lighter, the density is only 0.91g/cm3. Smaller than water. Among the general-purpose plastic particles, PP recycled particles have good heat resistance, and their thermal deformation temperature is between 80-100 degrees Celsius, which can be boiled in boiling water, and the molding temperature is between 160-220 degrees Celsius. The specific gravity of PP recycled material is 0.9g/cm3 to 0.91g/cm3. The mold shrinkage is between 1% and 2.5%. PP recycled materials have good stress cracking resistance and high bending fatigue life. The comprehensive performance of PP recycled material particles is better than that of PE plastic particles. PP recycled material light weight, good toughness, good chemical resistance.

With the emergence of more and more materials on the market and the emergence of our recycled PP materials in the building materials market, it is also a relatively good application. And in recent years, it has gradually been accepted by more building materials markets, so the development is relatively smooth.

As for thisPP recycled materialApplication in the building materials industry, mainly used to make a variety of insulation building materials. At the same time, the production of this material has certain advantages in cost, and it can also occupy a certain market in performance.

Moreover, after our PP recycled materials are made into building materials, their non-flammability and flame retardancy can meet national standards. And a large number of experiments have proved that our materials are better than most products in terms of flame retardancy. At the same time, by adding various additives, their performance development is also excellent.

Here we take a look at PP recycled material molding method is what kind?

Paste extrusion: a method of making polytetrafluoroethylene and additives into paste, then squeezing (pushing) out with a plunger, drying, and sintering to obtain the desired product. This method is commonly used in the manufacture of covered wire, small diameter tubes, rods and tapes, etc.

Post-pressing: A method of molding polytetrafluoroethylene and other products with high dimensional accuracy. The process is to put the freshly sintered part into the molding die and cool it to room temperature under the holding pressure condition.

Post-curing: After molding, the thermosetting resin is completely cured by standing or heating.

Post-forming: Post-forming of incompletely cured thermosets under heat and pressure.

Through the abovePP recycled materialI believe everyone has a lot of knowledge about this aspect. PP recycled materials are used more and more widely, is a very good product, for our production and processing to provide a lot of help. We are the manufacturer of PP recycled materials. If you want to know more about this, please contact us. We can introduce you from different aspects. We only have a clear understanding of the characteristics of PP recycled materials and the use of precautions to be able to make better use.

Related News

Follow Us

Dongguan huazuan plastic material Co., Ltd.

Add.: No. 78, Qiaoli Beimen Industrial Zone, changping town, Dongguan City

Tel: +86-0769 82020719

Sales one: Mr. Chen +86-13802397965

Sales 2: Miss Xia +86-13922971175

Sales 3: Miss Feng +86-13922918732

Fax: +86-769 82308699

Email: lindaxia@cnhzsj.com

Copyright©2023 Dongguan huazuan plastic material Co., Ltd. All Rights Reserved

绿美佳塑胶

Online Message