What are the characteristics and uses of PP recycled materials? How to reduce its gloss?

Release time:

2023-01-10

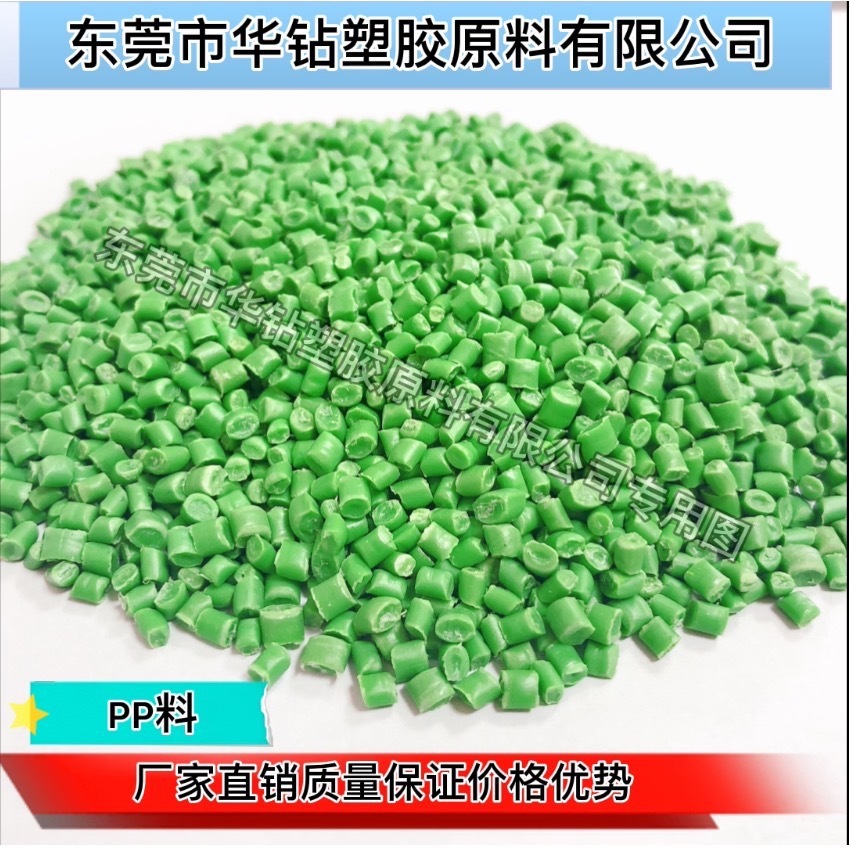

After the waste plastic is processed into PP recycled material, it only changes its appearance and shape, and does not change its chemical characteristics. They still have good comprehensive material properties, can meet the technical requirements of film blowing, wire drawing, pipe drawing, injection molding and extrusion, and are widely used in the production of plastic products.

Processing of waste plasticsPP recycled materialAfter that, it only changed its appearance and shape, and did not change its chemical characteristics. They still have good comprehensive material properties, can meet the technical requirements of film blowing, wire drawing, pipe drawing, injection molding and extrusion, and are widely used in the production of plastic products.

PP recycled material is no poison, odorless, tasteless milky white crystalline polymer, high crystallinity, structured, so it has excellent mechanical properties, its yield strength, tensile strength, compression strength, hardness and elasticity are higher than HDPE. Its melting point is 164~170. The product can be sterilized above 100. The chemical stability of polypropylene is very good, in addition to being attacked by concentrated nitric acid, it is stable to other chemical reagents. Processing methods: injection molding, extrusion molding, hollow molding, rotational molding;

The use of PP recycled materials mainly includes the following four aspects.

1. Re-manufacture PET bottles.PP recycled materialIt cannot be used for direct contact with food, but it can be used for the middle layer of a three-layer PET bottle and then made into a carbonated beverage bottle.

2. Spinning to make fibers. Recycled PET materials can be used to spin into fibers, used as pillow cores, mattresses, sleeping bags, felts, etc.

3. Glass fiber reinforced materials. The glass fiber reinforced material made of PP recycled material has good heat resistance and mechanical strength, and can be used to manufacture automobile parts, such as heat-resistant automobile wheel covers, whose thermal deformation temperature can reach 240 degrees. The flexural modulus was 9500MPa, the flexural strength was 214 MPa, and the impact strength was 15kf/m2.

4. Blending modification:PP recycled materialIt can be blended with other polymers to prepare various modified materials. If blended with PE, the impact properties of PET blends can be improved, and the ratio of PE: PET is (10~50): (90~50). If a small amount of polypropylene is added, the dimensional stability of the blend can be significantly improved. Due to the large difference in polarity between PE and PET, compatibility treatment is required during blending. Generally, the compatibility is improved by graft modification of the polyolefin.

How to reduce the gloss of PP recycled materials? The gloss of PP recycled materials can be reduced from the following four aspects.

1. optical refraction extinction

Based on the diffuse reflection principle of mold twill mirror or convex mirror, the extinction is realized by the color change caused by optical refraction or the wave front light affecting the imaging effect.

2. coating matting

When powder coatings with different curing speeds are mixed by dry mixing method, the gloss of the obtained coating film is obviously reduced and the matting effect is played.

PP recycled material: Due to the fast curing of the powder coating with high reactivity, the leveling and reaction of the slow curing resin of the continuous phase are hindered, and the final cured coating film loses gloss. While this approach is effective, it adds to the manufacturing process and cost.

Fillers having a matting effect are 3. added.

The addition of superfine silica, talc and other fillers significantly reduced the gloss. In particular, the particle size of the filler has a great influence on the gloss of the plastic. The larger the particle size, the lower the gloss. Commonly used matting agents are ultrafine silica, talc, aluminum stearate and calcium stearate.

4. addition of low molecular weight thermoplastic resin matting.

Related News

Follow Us

Dongguan huazuan plastic material Co., Ltd.

Add.: No. 78, Qiaoli Beimen Industrial Zone, changping town, Dongguan City

Tel: +86-0769 82020719

Sales one: Mr. Chen +86-13802397965

Sales 2: Miss Xia +86-13922971175

Sales 3: Miss Feng +86-13922918732

Fax: +86-769 82308699

Email: lindaxia@cnhzsj.com

Copyright©2023 Dongguan huazuan plastic material Co., Ltd. All Rights Reserved

绿美佳塑胶

Online Message